Mesin pipa berliku dinding berlubang berlubang besar

mengirimkan permintaan

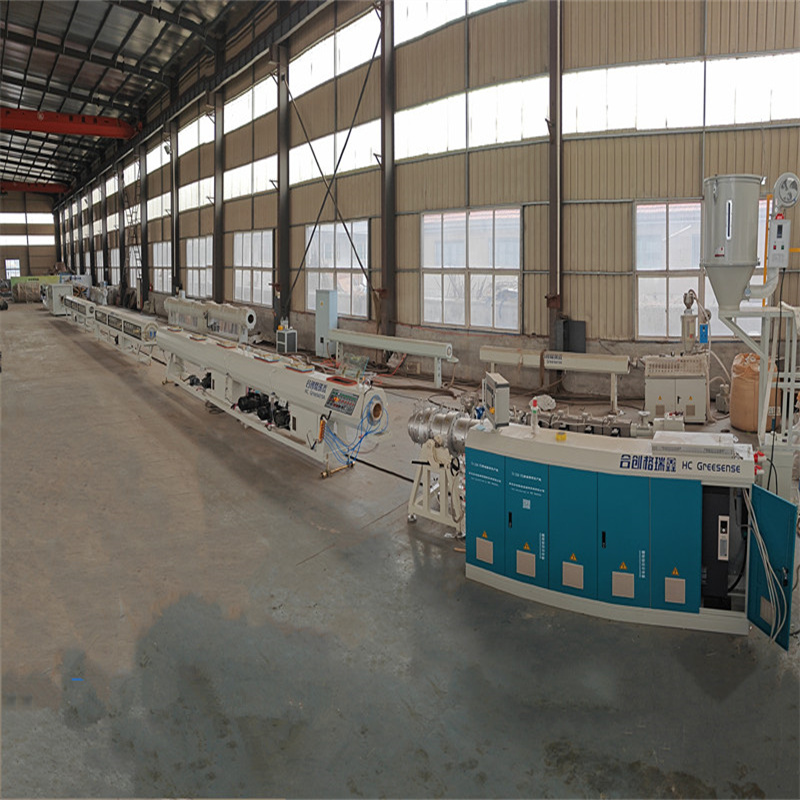

Hollow wall winding pipe equipment

HDPE hollow wall wrapped pipes have been successfully used as drainage pipes to replace cement pipes and cast iron pipes, and have broad market prospects. Our company is an authoritative manufacturer of large diameter hollow wall winding pipe machine in China, with strong technical advantages and rich experience in implementing production and installation. The equipment design is advanced, the configuration is high-end, the operation is reliable, the service life is long, and the output of the same model is far higher than the industry level. Especially for ultra large diameter models, we have rich experience and can meet the needs of large high-end customers at home and abroad. The performance indicators of the production line have reached the international leading level.

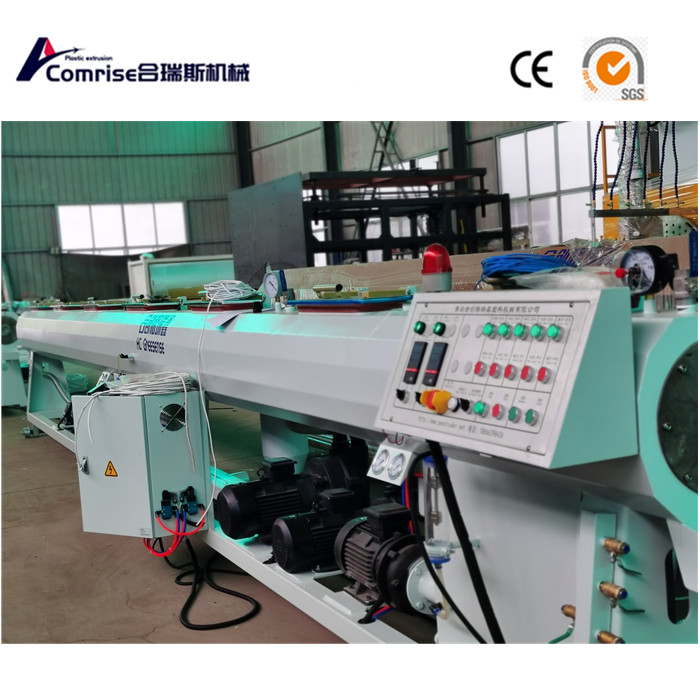

1.HDPE Plastic pipe making machine Feeder ,Drying hopper and Extruder

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality

extrusion.

(1) Motor brand: Siemens

(2) Inverter brand: Delta

(3) Contactor brand: Siemens

(4) Relay brand: Omron

(5) Material of screw and barrel: 38CrMoAlA.

(6) Heating method: Ceramic or cast aluminum heating

2. HDPE Plastic Coiled Pipe Extusion Die head

The mould is made of high-quality alloy steel, the internal flow channel is chrome-plated and highly polished, which is wear-resistant and corrosion-resistant; With the special sizing sleeve, the product production speed is hight and the surface of the pipe is good

3. Vacuum calibration water tank and Water cooling tankIt is stainless steel materials.

It could be water leaching cooling way or water spray cooling way according pipe diameters and extrusion speed.

(1) Vacuum pumppower : 4 kw

(2) Water pump power: 2.2 kw*2

(3) Spray cooling: ABS nozzle; Stainless steel pipe

(4) Stainless steel material: 1Cr18NiTi

(5) Diameter of tank : Customized

(6) Length of tank: 6 m

4.HDPE Plastic Pipe Haul-off machine

The main function of the tractor is to clamp the pipe after cooling and forming, and transport the pipe forward smoothly and evenly by providing a certain traction speed and traction force.

5.Cutting machine

The special cutting machine for PVC pipe adopts rotary clamping device, is suitable for different pipe diameters, avoids the

trouble of frequently changing clamping device.

(1) Cutting motor power: 1.5 kw

(2) Cutting scope: Customized

(3) Control means: Pneumatic control

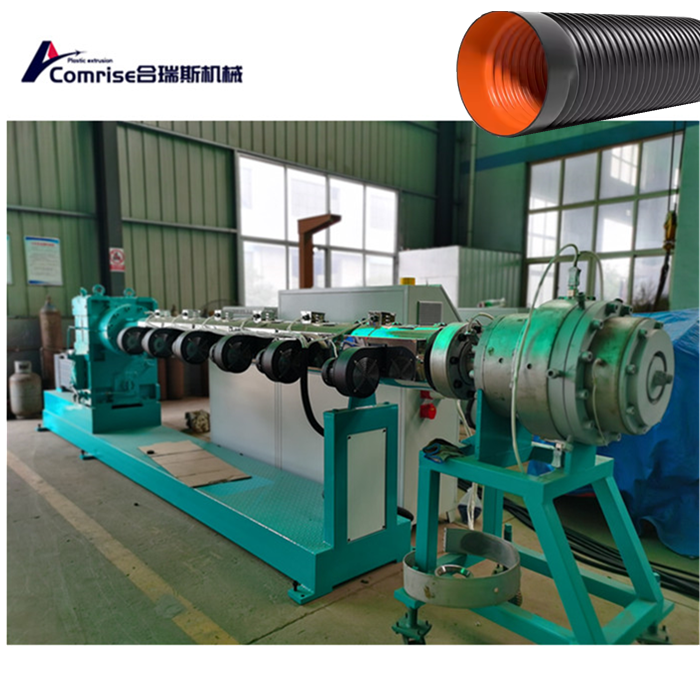

6.Plastic spiral winding machine

The spiral winding machine, which ar produced by Qingdao Comrise Plastic mahcinery,efficient and energy-saving, stable operation,easy to install and disassemble

GET A QUOTATION NOW